The complete story of what happened remains unknown. Nevertheless, it poses a major question of fire safety and about the storage of hazardous goods. The explosion resulted from the unsafe storage of a large depository of ammonium nitrate in one of the port’s hangars, a shipment that was supposed to leave the port in a few days but ended up staying for 6 long years.

Industrial safety

When talking about industrial safety- a category in which a port with several hangars and a wide variety of goods would fall under- safety barriers are of utmost importance. The more exhaustive this list of barriers is, the less likely for major events to take place. Here we would recall the swiss cheese model, in which each of the holes in the slices would represent the weaknesses of each barrier. For a high-risk event to happen, it would need to simultaneously pass through all the different “slices” or barriers. In such locations as Beirut port, lots of performance requirements fulfill the various functions for each of the barriers and maintain their integrity. Those performance requirements include, but are not limited to layout and arrangement, containment, ventilation, ignition source control, active fire protection, passive fire protection, escape and evacuation, etc.

Layout and arrangement

One of those main performance requirements would be the “layout and arrangement” of the different elements, functions, and uses within the port location. Such a requirement provides both, preventive and reactive function to incidents. For example, if the layout of explosive materials is placed out of proximity to ignition sources, a safety barrier is automatically in place, and that’s on preventing a safety breach. Reacting to a safety breach would be in how the layout would be able to contain the risk or fire in this case and keep it from spreading. A successful layout and arrangement plan would be able to distinguish the dangerous goods from the non-hazardous areas, which in turn would dramatically reduce the severity of what happened at Beirut port, or at least prevent the “nuclear-like” explosion that took place after the initial fire. The layout and arrangement of an industrial zone will most certainly affect all the other safety barriers at the facility. It provides the foundation layer upon which all the other barriers will be designed, which in turn marks its high importance.

Safe storage?

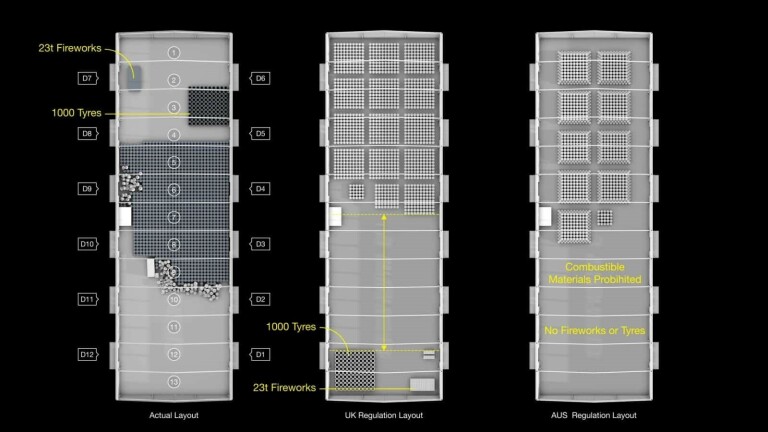

If we are to focus solely on the layout performance requirement and take a scientific look at what took place at Beirut’s port, the number of issues we can deduce is quite significant. In November 2020, the Forensic Architecture team collaborated with Mada Masr to release a report detailing the investigation that they conducted on the Beirut Port Explosion incident. To do that, they examined open source information including videos, photographs, and documents to create a timeline and a precise 3D model of what happened. They were able to identify four separate smoke plumes coming out of different parts of the warehouse (the hangar that contained the ammonium nitrate). Those four distinct fire plumes indicated the presence of different stored materials, which should not have placed together under an effective layout safety barrier. Some of the materials located in close proximity to the Ammonium Nitrate included fireworks and car tires, hence a major fire hazard by themselves. Gareth Collett CBE, an explosives expert for the UN, specifically stated that “the arrangement of goods within the building was the spatial layout of a makeshift bomb on the scale of a warehouse, awaiting detonation.” As ammonium nitrate is highly unlikely to explode if stored correctly, it mimics a huge bomb when confined and contaminated with other additives, hence the necessity of its safe storage. Lebanon abides by the NFPA and the French regulations in terms of fire safety, which are quite similar to the image below.

Negligence of the people in charge

That being said, what happened was not the failure of multiple safety barriers that led to an event of such magnitude. It was simply the multi-layered negligence of the people in charge, those who chose to sit on a literal bomb rather than take very simple measures to avoid the inevitable. There were no various barriers put in place, a system that would be intuitive in such a large-scaled industrial zone. The basic and most important performance requirement was neglected, and the people of Beirut have paid the price.

Major incidents are usually the main drive behind the change of regulations, they can literally move mountains and make huge shifts in the whole safety culture of a nation. The only thing we can hope for is for the same to happen in Lebanon. 6 months after the tragedy, this does not seem to be the case.

Om journalisten:

Amani er en libanesisk arkitektingeniør med en spesiell interesse for fagfeltet sikkerhet. Hun matet den interessen ved å ta en mastergrad i brannsikkerhet ved Høgskulen på Vestlandet (HVL). I 2020 ble hun uteksaminert og har siden begynnelsen av 2021 jobbet som Graduate Fire Engineer ved Arup UK. Hennes lidenskap er å kunne oppnå et bedre samarbeid og en enighet mellom arkitektbransjen og fokus på brannsikkerhet, som vil føre til at ulike designprosjekter vil bli tryggere.

https://forensic-architecture.org/investigation/beirut-port-explosion#resources