Types of fire protection: Active and Passive

Fire protection elements are mainly distributed into active and passive systems. Active ones are those that require any form of actuation, i.e. they need a trigger to initiate their function. Examples of those can include sprinkler systems, smoke protection systems such as dampers and AOVs (Automated Open Vents) usually installed on the top of stairs, etc. On the other hand, passive fire protection consists of elements that are always there, regardless whether there’s a fire or not. These include fire doors, fire resisting construction, penetrations that are fire stopped, etc. To make things a bit clearer, a fire resisting wall is a passive fire protection measure while a fire and smoke curtain is an active one. Even though they basically perform the same function, a fire curtain requires actuation, usually from a detector, to deploy, thus making it an active measure. This article will focus on passive fire protection only.

Passive fire protection and Performance Qualifications

Passive fire protection is an essential component of fire strategies. To be able to accurately specify those requirements, it’s important first to understand the performance qualifications of various building elements, and why each element would require different combinations of those.

Whenever a certain component is assigned a specific fire resistance rating, such as “30 minutes fire resistance”, it should always be clarified as what this period is referring to. These classifications can include one, or a conjunction of, loadbearing or stability, integrity, insulation, and radiation. Other criteria can also include hot and cold smoke leakage, mainly used for doors, fire curtains, and ducts/ dampers.

Loadbearing capacity is how an element behaves under fire exposure and how long it can maintain its structural stability without collapsing or distorting excessively. Integrity is how long an element can withstand fire exposure on one side without transmitting it to the other side. Insulation is how long an element can withstand fire on one side without transmitting heat to the other side. Radiation is how long an element can withstand fire exposure on one side without transmitting it through radiation to the unexposed side. Radiation is typically used in cases where insulation cannot be achieved but occupants are expected to escape within the proximity of that element. It is thus used to main tenable escape within that area, such as beside fire curtains for example. Thus, these performance qualifications are used differently based on the type of element being assessed. For instance, a non-loadbearing plasterboard wall does not need to achieve any loadbearing capacity, while a steel column would, and so on.

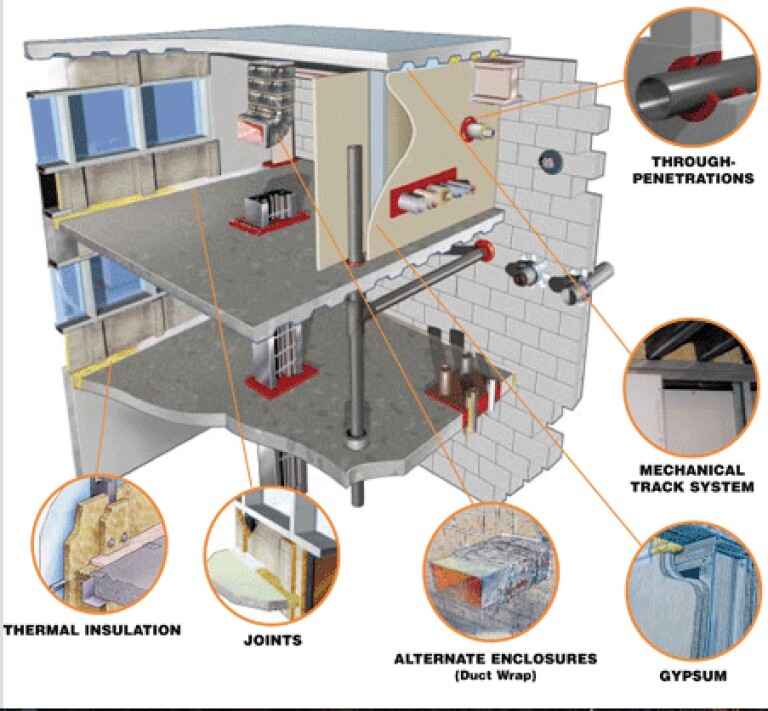

Service Penetrations and Firestopping

As most fire resisting walls or floors will inevitably be penetrated by mechanical or electrical services, the challenge becomes in maintaining the same standard fire resistance despite that penetration. This is where fire stopping comes into play. When not performed correctly, compartment walls and floors lose their ability to contain fire and smoke and thus risk the fire integrity of the building. Fire stopping is the term used to describe the systems that maintain the period of fire resistance for a wall or floor. These products are tested with particular services and configurations and must demonstrate through fire testing that they can achieve the required performance.

Types of firestopping products

There are a number of fire stopping products and the market is constantly innovating with new and improved ones. The main ones include intubatts (also known as fire batt), intumescent mastic and paints, pipe collars and wraps, cushions or pillows, and mortar compounds. Each of those is used for various penetrations and can achieve different period of fire resistance.

Design, product, and installation compliance

Fire stopping can be very tricky in determining how it can correctly achieve its function. For example, a product might be design correctly but manufactured to a lower standard, or perhaps applied to an element it does not work well with. For example, pipe collars are used to fill in gaps resulting from a plastic pipe melting in a fire. The intumescent components of the collar will expand almost immediately and fill in the whole gap. This makes pipe collars irrelevant to be used on steel pipes for instance.

The installation compliance is based on how the contractor actually installs the fire stopping product. As these products are tested on very specific items and materials, changing any small detail would lead to the probability of the whole system failing. A small detail can be as tiny as a screw type or a fitting steel angle. Thus, it is very important for fire engineers to be very vigilant in how they review and approve site details. Another very important skill is exposure to site work which will help them identify those seemingly minor issues. Hence, design, product, and installation compliance are all equally as important in successful fire stopping, throughout the various design phases.

Cavity barriers

Before I moved to the United Kingdom, cavity barriers were something I had never heard of before. Nevertheless, it is one of the most topics discussed here. As concealed cavities and various empty spaces within floors, walls, ceilings, and roofs are an easy route for the spread of fire and smoke, this can result in unseen fire spread that would not be detected on time. Thus, cavity barriers are a passive fire protection measure used to separate fire resisting construction within those voids, thus acting as a fire compartment within them. Cavity barriers should be installed at the junction between an external cavity wall and every compartment floor and compartment wall. While cavity barriers fill concealed internal gaps within external walls, ceilings, and other building parts, fire stopping fills visible gaps around internal openings or joints in fire rated walls or floors. They become increasingly important in high rise buildings, especially with the façade fire risks. They can basically prevent a façade risk from spreading and even reaching interior spaces within the building.

Types of cavity barriers

Cavity barriers are mainly separated into two types, open state cavity barriers and closed state cavity barriers. As the name suggests, open state cavity barriers are those that are kept open until triggered, hence making it an active fire protection measure. Closed state cavity barriers, on the other hand, are a passive fire protection measure as they maintain their function throughout normal and fire situations. As with other fire prevention measures, they both require specific design, product, and installation compliances standards.

Communication and Coordination

The more fire engineers can work closely with contractors throughout various stages of the project, the more errors can be detected early on. It’s always about communication and effective coordination, and that will inevitably always be the case.